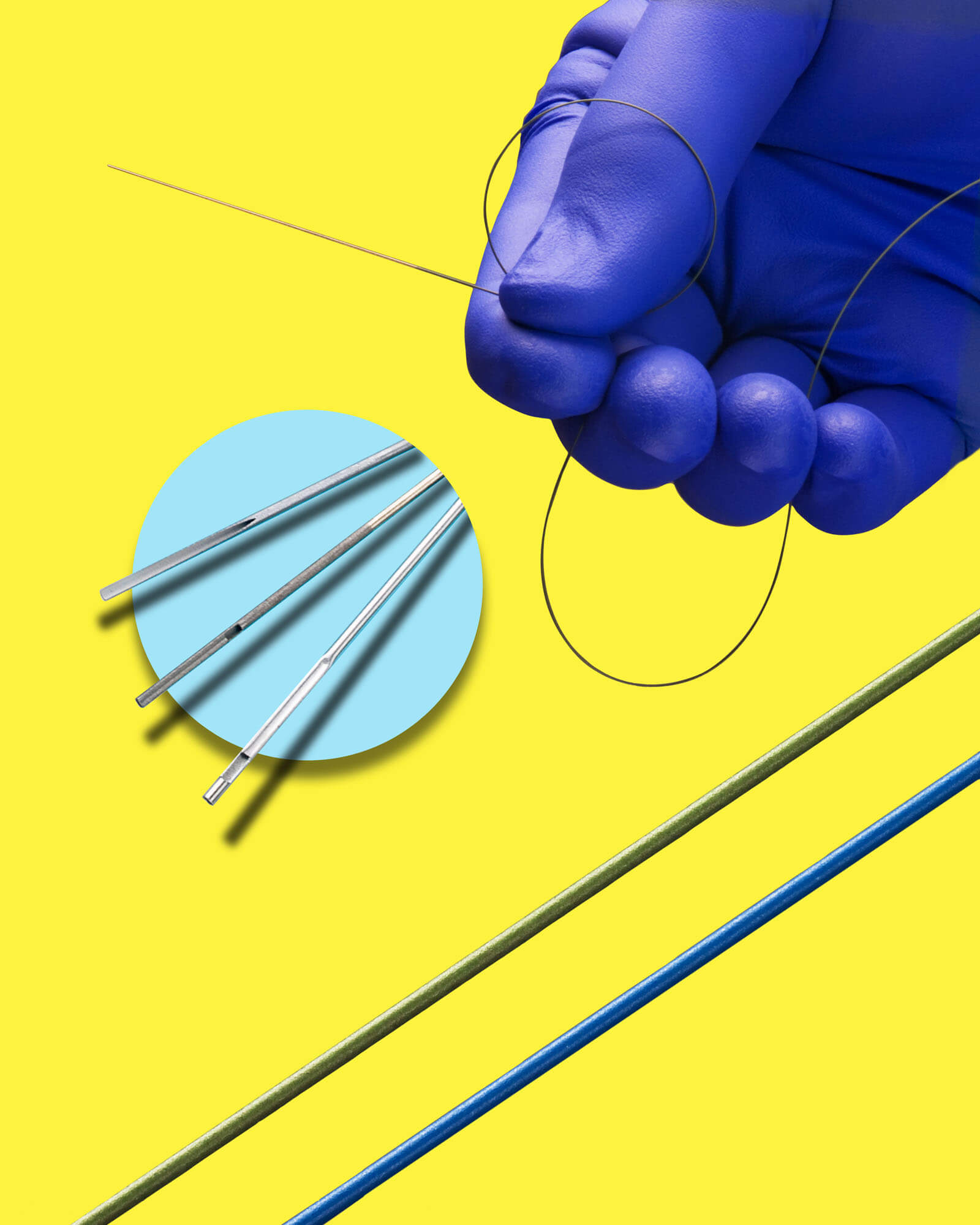

A PTFE coating service for teflon coated guidewire, with kink-resistant nitinol tube and stainless steel tube that are used in cardio vascular medical devices for arterial transfer is available from Applied Plastics, Inc. of Norwood, Massachusetts.

Applied Plastics’ PTFE Coated Nitinol Tube features a highly lubricious coating while maintaining the kink-resistant characteristics of the nitinol tube and can be processed in sizes from 0.002” O.D. up and lengths to 10 ft. Suitable for guide wire, catheters, needles, and other devices, the PTFE coating can be applied with coating tolerances from 0.0001” to 0.0003”.

Available in green, grey, blue, and black colors, Applied Plastics’ PTFE Coated Nitinol Tube can incorporate marker bands at user-specified inter-vals. This PTFE coating service is available for all hypotube variations including spiral, skived, flared, crimped, ground, and slotted types.

Applied Plastics’ PTFE Coated Nitinol Tube is priced according to size and quantity. The firm can also source the tubing where required. Samples and literature are available upon request.

For more information about Teflon Coated Guidewire solutions, contact:

Applied Plastics Co., Inc.

25 Endicott St. / P.O. Box 128

Norwood, MA 02062-0128

(781) 762-1881

[email protected]