Engineered Coating Solutions

Best-in-class coating solutions

Medical Devices are becoming more complex. To meet these advancements in medical procedures you need a partner that can collaborate with you to meet your engineering requirements and quality standards. Applied Plastics has the experience and expertise to support you with skilled engineering support resources and superior products.

Our Quick Ship Selection

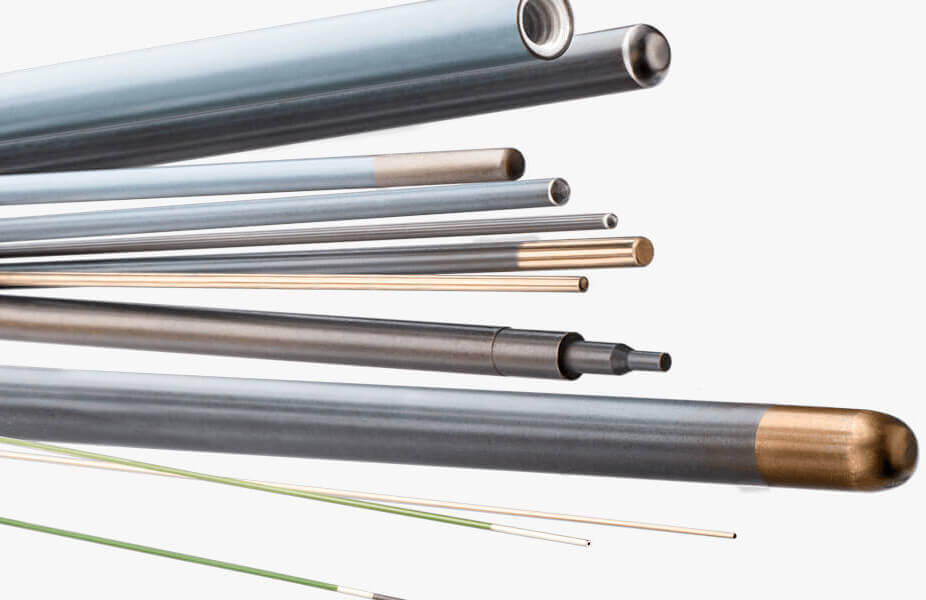

Coated Mandrels

Our best-in-class PTFE coated mandrels aid in the manufacturing of advanced catheter systems

Coated Fine Wire

We coat fine wire with a thin, smooth, lubricious coating for optimum release or slip properties

Coated Hypotubes

We offer a class-leading PTFE coating service for stainless steel and nitinol hypotubes.

UNCOATED STAINLESS STEEL WIRE & MANDRELS

For your convenience while shopping online.

COATED ABLATED PULL WIRE

The PTFE Natural® Coated Ablated Pull Wires offer exceptional performance and weldability.

Exceptional PTFE Product Design Starts with an Exceptional Partner

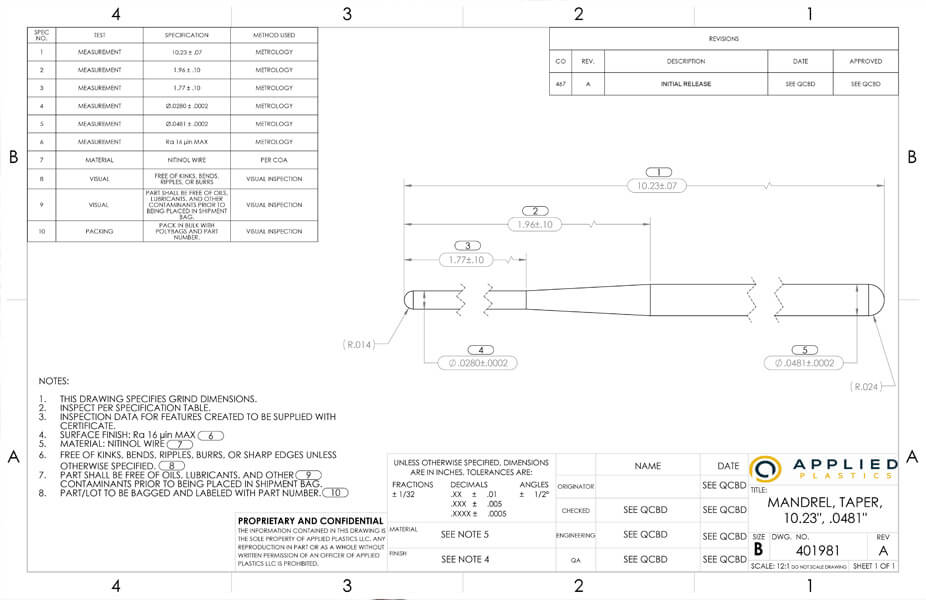

Applied Plastics is a leading manufacturer and supplier of coated components to the advanced catheter industry. We can maintain the tightest tolerances and apply a superior lubricious coating to mandrels and fine wire used in catheter manufacturing.

-

- Partner for prototyping and volume production

-

- Best in class tolerance capabilities to +/- 0.0001

-

- Superior lubricious Proprietary PTFE Natural® coating solution with a low coefficient of friction

-

- Unmatched coating bond strength, durability, and temperature resistance

Medical device markets supported by Applied Plastics:

Interventional

Neurovascular

Structural Heart

Endovascular

Minimally Invasive Surgery

Peripheral Vascular

Cardiovascular

Endoscopy

Urology

Women’s Health

Robotics

Learn more about our products and the engineering design process.

It's great to be number one.

"Having been in business all these years, it’s great to be number one - known as the best - someone that impresses your customers."

DAVE RING, EXECUTIVE CHAIRMAN

Superior medical devices require superior coatings.

Our proprietary PTFE Natural® coated mandrels offer unmatched benefits.

Low Coefficient of Friction

PTFE Natural® coatings provide a coefficient of friction generally in the range of 0.05µ to 0.20µ, based on load and sliding speed.

HEAT-RESISTANCE

PTFE Natural® coatings can operate continuously at temperatures up to 550°F and can be used for intermittent service up to 600°F with adequate ventilation.

Non-Stick

Virtually no solid substances permanently adhere to PTFE Natural® coating

CHEMICAL RESISTANCE

Most chemical environments do not affect PTFE Natural® coatings.

ROBUST COATING

The proprietary PTFE Natural® coating process enhances the substrate bonding surface to provide optimum lubricity without flaking or cracking.

NON-WETTING

PTFE Natural® finishes are hydrophobic allowing for easier and more complete cleanup.

Coating Solutions We Can Apply

Materials We Coat

We’re thrilled to share some exciting news with you! Erik Wendehost, our very own Director of Sales at Applied Plastics, has been chosen as the moderator for the upcoming Catheter Development & Manufacturing Panel at the MPP Event in Maple Grove, Minnesota, on June 13th. With over two decades of experience in the MedTech industry, […]

Exciting news! Applied Plastics’ online store shopping experience has added new functionality highlighting the ease of use of shopping online– we’re now offering ordering with no credit card required. Seamlessly place orders using your Purchase Order, and enjoy the convenience of Net 30 terms. In addition, users can now use their FedEx or UPS shipping […]

We're ready to help.

Let our engineers help you find the right product or coating to match your application requirements and design needs. Contact us using the form below or call 781-762-1881.