The PTFE Natural® Difference

PTFE Natural® is a proprietary process providing you with a superior coated product that is the most lubricious and robust available to support your catheter design. Our expertise and superior coatings allow us to assist you in designing the most efficient solutions for manufacturing and delivering your products.

Not only does PTFE Natural® provide a lubricious coating it is also robust and ideal for applications requiring heat or abrasion resistance.

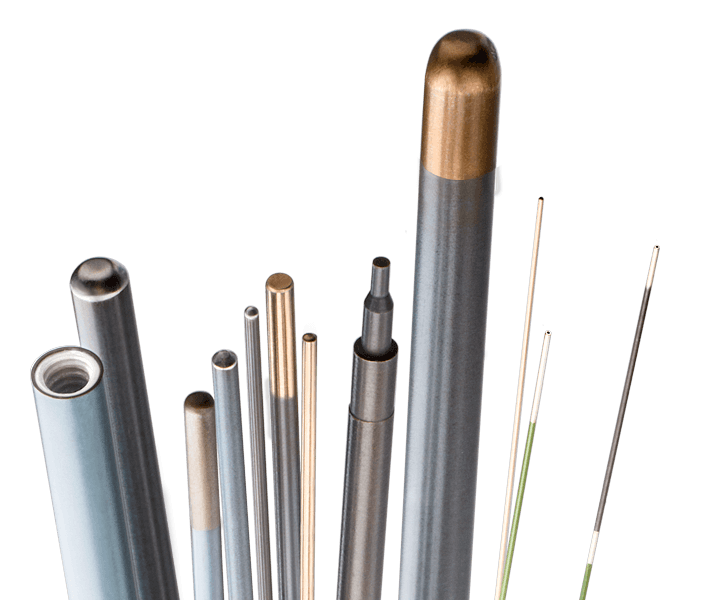

The highly engineered processes that Applied Plastics uses to manufacture our coated products allows us the unique ability to hold very precise outside diameter (OD) tolerances. These precise processes make our products ideal for use in catheter manufacturing and as part of the device delivery system. Our coated products are used in manufacturing as tipping and welding mandrels, reflow mandrels, core wires, and pull wires. Our precision and lubricious coatings also make our products ideal for pull wires and guide wires for highly engineered catheter systems.

Availability is vital.

The rapidly evolving medical device market requires short lead times which is why Applied Plastics is the design and manufacturing engineers first call.

We carry a wide variety of material for your every need from fine wire to large mandrels and hypotubes, many of which are available in our online store for quick turn requirements. Visit our online store for more details.

PTFE Natural® Solutions are the engineers’ secret weapon when designing and manufacturing advanced access, delivery and closure systems.

All PTFE coatings are not the same

Reference guide for comparing PTFE Natural® to our other PTFE coatings

| Coating Name | PTFE Natural® | OTHER PTFE COATINGS OFFERED |

|---|---|---|

| Standard Tolerances

We Can Hold | .005" - .039” (+/- .0003”)

.040" and higher (+/- .0005”) | +/- .0005" |

| Wire Types & Materials | Various Stainless Steels Nitinol Wire Silver Plated Copper Wire For all other requests, Contact Us | Various Stainless Steel Nitinol Wire Silver Plated Copper Wire Hypotubes |

| Colors | PTFE Natural® Select colors available upon request | Natural, Black, Blue, Green, Gray |

| Primary Uses | CATHETER MANUFACTURING AID

| CATHETER MANUFACTURING AIDS,

COMPONENTS AND PRODUCTS

|

| Supplied | Straightened & Discrete Cut Lengths | Straightened & Discrete Cut Lengths |

| Biocompatibility | Customer responsible for biocompatibility of entire finished device | Customer responsible for biocompatibility of entire finished device |

| Coefficient of Friction | Exceptional | Good |

| Heat Stability | Up to 500°F (260°C) with intermittent processes up to 550°F (288°C) | Good |

| Chemical Resistance | Mild | Mild |

| Abrasion Resistant | Yes | Yes |

PTFE Natural® and other PTFE coated components are not authorized for use in permanent implants.

Coating and Substrate Guide

PTFE Natural® Coating Options

| Material | Tensile Strengths | Types of Wire |

|---|---|---|

| Stainless Steel | 302, 304, 316, SLT, M2 | Round, flat cut discrete lengths |

| Nitinol | Variety of surface finishes | Round, cut discrete lengths |

| Silver Plated Copper | Round, cut discrete lengths |

All Coatings & Finishes Available

Beyond having access to hundreds of standard coating products from DuPont‚ 3M, Pennwalt, Whitford, and other leading suppliers, what is most important is that at Applied Plastics we know how to select the best product, custom formulate when necessary, and choose the best coating method for your application. Most of the coatings we use are environmentally-friendly and contain no solvents. Functional coatings can be applied in a wide range of colors in nylon, polyester, and epoxy, depending upon the nature of the material being coated and your desired surface properties. Finishes can have amatte, gloss, textured, or wrinkled appearance.

Teflon® PTFE

This nonstick coating has the highest operating temperature of any fluoropolymer (260°C, 500°F continuous), an extremely low coefficient of friction (0.05 to 0.20), and good chemical resistance. This finish is hydrophobic and oleophobic, permitting faster and more complete clean-up.

Teflon® FEP

This nonstick coating melts and flows during baking to provide nonporous films. In addition to a low coefficient of friction, it provides excellent chemical resistance.

As an experienced PTFE coating supplier, we apply a robust PTFE coating to provide a consistent and lubricious surface finish on the below materials.

- Aluminum

- Silver Plated Copper

- Stainless Steel

- Titanium

- Nitinol

Contact Applied Plastics

If you have a question, or a coating project you’d like to speak with us about, please feel free to use this form. We’re happy to work closely to identify your surface finish & lubricity needs, and help select the method of application to optimize your product performance. We are committed to providing a consistent coating and quality service. All inquiries will be responded to in a timely fashion.