Q: What is the tolerance range you can hold?

A: Standard tolerances +/- .0003” to +/- .0005” pending substrate starting diameter. Consult directly with us to discuss tighter tolerance requirements.

Q: What do you want your coating to accomplish?

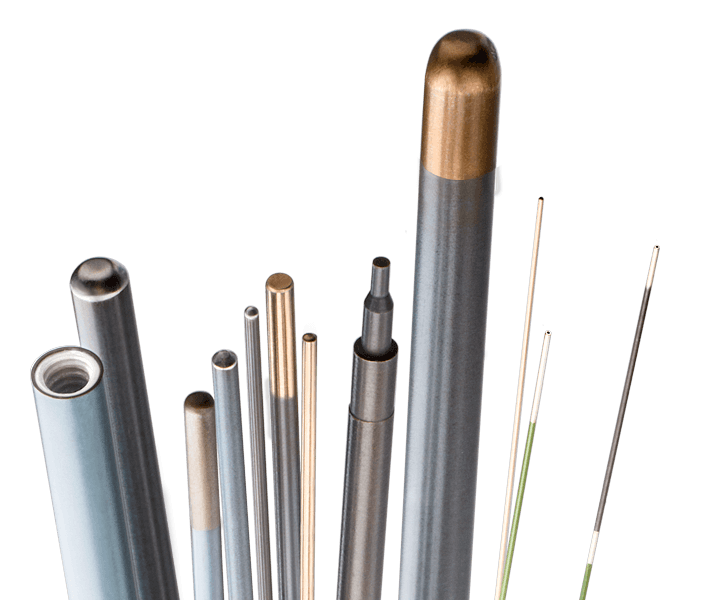

A: Applied Plastics specializes in helping you select the right coating for your application and always seeks the optimum balance between performance and cost. We have coated parts ranging from electronic components to heavy machinery and from medical instruments to hand tools. Capable of coating parts ranging from fine wire for cardiovascular medical applications to 4,000 pound industrial castings, we know from our vast experience when to apply each type of coating, how thick they should be for a specific purpose, and by which method they should be applied.

Q: Does Applied Plastics work with Teflon® Coatings?

A: Founded in 1953, we are one of the original licensed industrial applicators of Chemours Teflon® finishes in the country and were one of the pioneers in the development of electrostatically applied powder coatings. Serving customers worldwide in virtually every industry, ranging from aerospace to medical, we know how to match the most appropriate coating and application technology to meet your precise requirements. Our skilled technicians understand the art and science of selecting, custom formulating, and applying functional finishes. We apply coatings that solve problems.

Q: What are some Applications for Coatings?

A: There are a wide variety of applications for our coatings. A brief list is shown below for your convenience.

- Abrasion resistance

- Non-stick

- Bio-compatibility

- Chemical resistance

- Corrosion resistance

- Salt spray resistance

- Cryogenic

- Dry lubricity

- Heat resistance

- Non-aging characteristics

- Non-wetting

- Low coefficient of friction

Q: What Coating Methods can Applied Plastics use?

A: At Applied Plastics, we can apply coatings by several methods including electrostatic spraying, electrostatic fluidized bed, conventional spraying, and various proprietary techniques for fine wire and hypotubes. To assure the best possible adhesion and surface finish, we employ a wide range of manual and automatic sand blasting and substrate preparation techniques. From surface degreasing through final curing, our skilled technicians perform all processes at our Norwood, Massachusetts facility. And to make sure that our quality is unparalleled, we use laser micrometers that can measure thickness tolerances of ±0.0001” or better.

Q: What Materials can be Coated?

A: There are several materials that Applied Plastics can coat. A list of those materials is shown below for your convenience.

- Aluminum

- Brass

- Bronze

- Copper

- Ceramics

- Steel

- Stainless Steel

- Titanium

- Glass

- Select Plastics

- Nitinol

Q: Does Applied Plastics stock PTFE coated mandrels?

A: Yes, within our online store, we stock a large inventory of PTFE Natural® coated mandrels in sizes from 0.007” to 0.100″ diameter, in 0.0005” increments from 0.007”-0.041”.

Q: Can Applied Plastics make custom mandrels?

A: Yes, we can make virtually any diameter. Submit your drawing online via our contact form or call us.

Q: Does Applied Plastics supply multi-diameter mandrels?

A: Yes, we custom produce a wide range of multi-diameter and tapered mandrels.

Q: Does Applied Plastics coat Nitinol wire?

A: Yes.