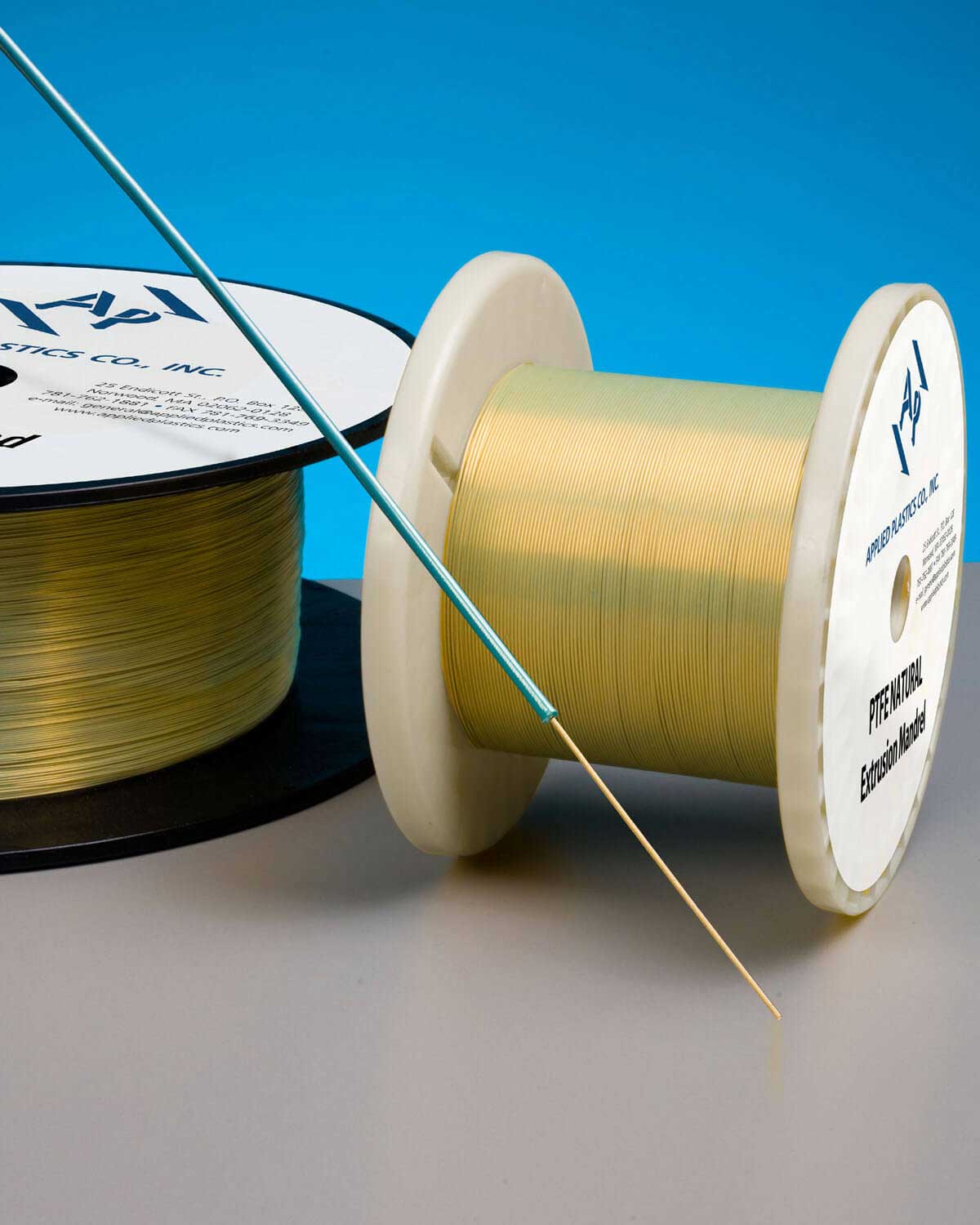

An extrusion mandrel for manufacturing and forming catheter tubing that provides a smooth, slippery surface to permit faster production is available from Applied Plastics Co., Inc. of Norwood, Massachusetts.

Applied Plastics’ PTFE Natural® Extrusion Mandrel is biocompatible and features a 0.5 dynamic coefficient of friction to provide a smooth, slippery surface which permits faster production. Designed for extruding small diameter catheter tubing, this silver plated copper wire with the PTFE Natural® coating is supplied in continuous lengths on spools.

Allowing over 25% elongation without flaking and failure, Applied Plastics’ PTFE Natural® Extrusion Mandrel is available in .010” to .080” dia. sizes with ±.0003” tolerance, depending upon size. This precision, anti-stick extrusion and forming mandrel is chemically inert and capable of withstanding up to 315°C (600°F) service.

Applied Plastics’ PTFE Natural® Extrusion Mandrel is priced according to size and quantity. Samples and price quotations are available upon request.

For more information contact:

Applied Plastics LLC

25 Endicott St. / P.O. Box 128

Norwood, MA 02062 USA

(781) 762-1881

[email protected]

appliedplastics.com