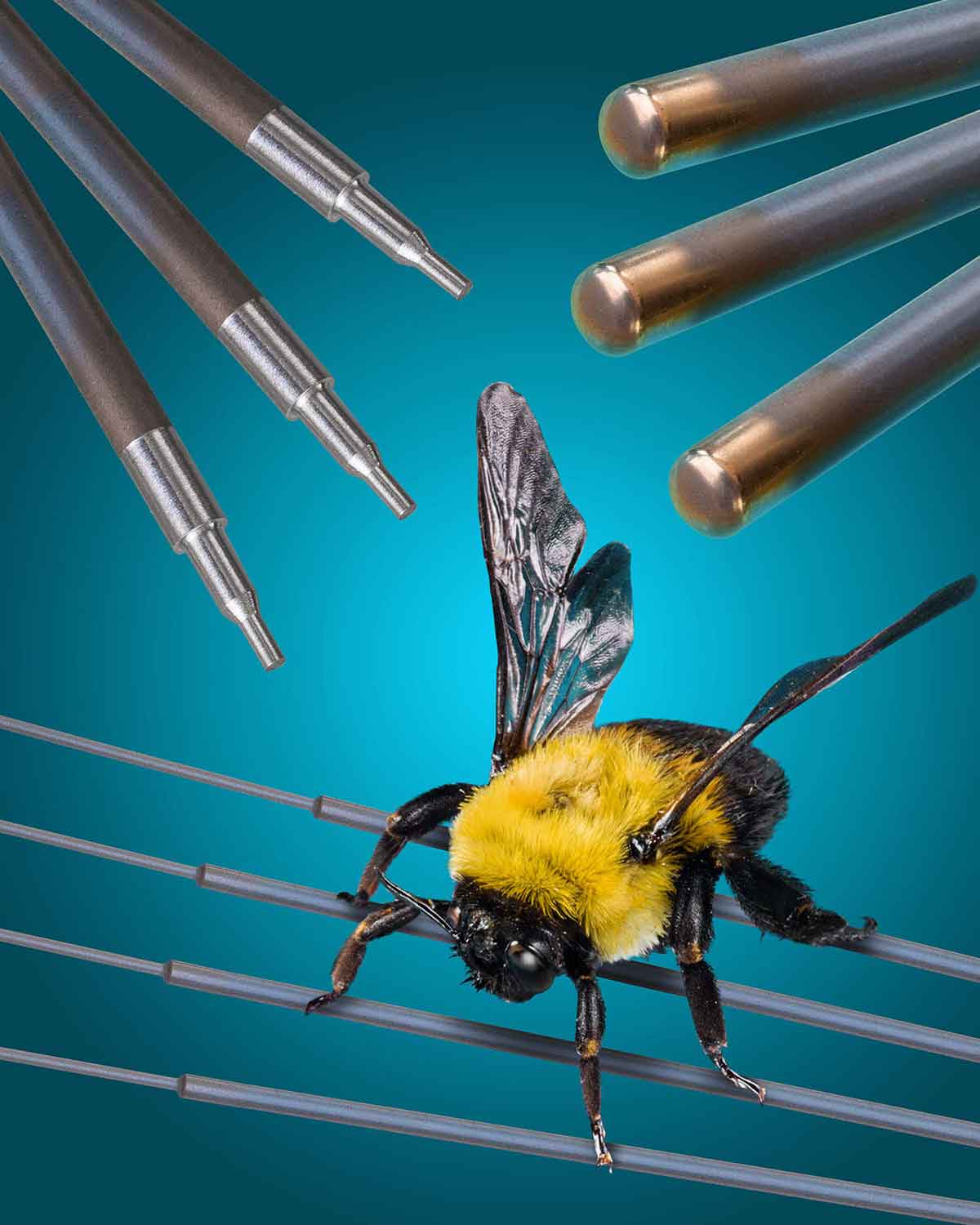

A service for refurbishing damaged fuse welding and tipping mandrels used for manufacturing catheters that restores them to pristine like new condition is available from Applied Plastics Co., Inc. of Norwood, MA.

Applied Plastics’ Forming Mandrel Strip and Recoat Service strips the old Parylene® and Teflon® coatings from fuse welding and tipping mandrels and applies a new PTFE Natural® coating that will not crack, flake, or peel. Ideally suited for larger diameter mandrels 0.020” and up, this precision coating service lets users recondition rather than discard worn mandrels which saves delivery time and eliminates grinding; especially with complex configurations.

Featuring a smooth anti-stick surface that withstands heat up to 300°C continuous, with excursions to 371°C, PTFE Natural™ coated forming mandrels provide a 0.05 coefficient of friction per ASTM-1894. After stripping the worn coatings, the mandrels are reconditioned and coated using a proprietary process which enhances their bonding surface and prevents cracking and flaking.

Applied Plastics’ Forming Mandrel Strip and Recoat Service is priced according to coating requirements and quantity. Quotations are provided upon request.

For more information contact:

Applied Plastics LLC

25 Endicott St. / P.O. Box 128

Norwood, MA 02062 USA

(781) 762-1881

[email protected]

appliedplastics.com