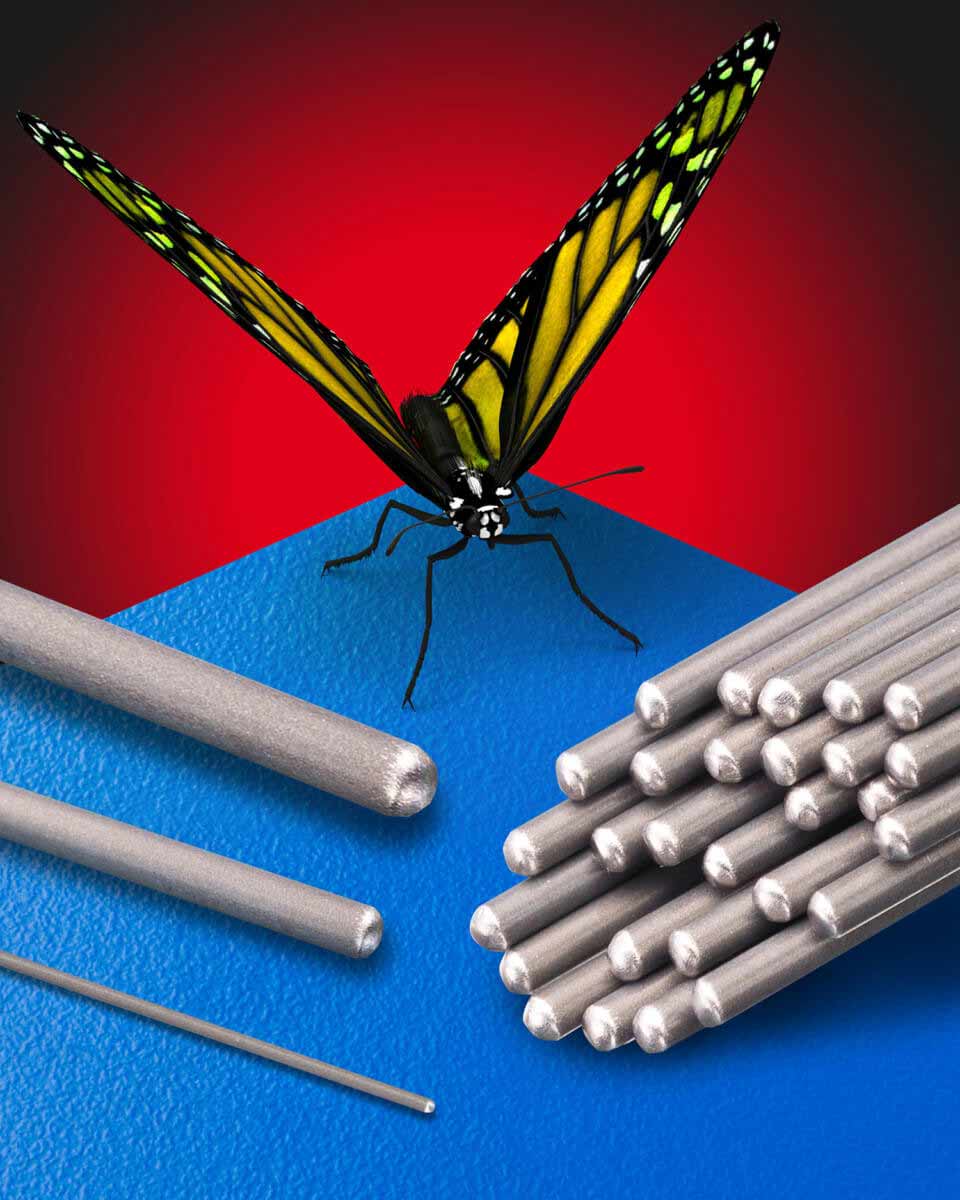

A full line of PTFE coated 304 stainless steel forming mandrels offered in full and half sizes for manufacturing small diameter catheters are available from Applied Plastics Co., Inc. of Norwood, Massachusetts.

Applied Plastics’ PTFE Natural® Grey Forming Mandrels are made from 304 SS and feature a proprietary surface preparation process and a zero-PFOA PTFE coating that will not crack, flake, or peel. Designed for fuse welding and tipping operations, the firm maintains a 50,000 piece inventory in full and half sizes from 0.005” to 0.060” dia., cut from 6” to 73” long.

Unlike green pigmented PTFE coatings which can flake and have adhesion problems, Applied Plastics’ PTFE Natural® Grey Forming Mandrels maintain their integrity to prevent the tubing from sticking and block shrinking to simplify catheter removal. Forming mandrels can also be produced in custom sizes and can be manufactured from Nitinol.

Applied Plastics’ PTFE Natural® Grey Forming Mandrels are priced according to size and quantity. Samples and quotations are available upon request.

For more information contact:

Applied Plastics LLC

25 Endicott St. / P.O. Box 128

Norwood, MA 02062 USA

(781) 762-1881

[email protected]

appliedplastics.com