Apply Our Coating to Your Mandrels.

Let Applied Plastics coat your product with our industry-leading coating.

We work closely with our customer’s to identify your surface finish & lubricity needs then we select the method of application to optimize your product performance. We are committed to providing a consistent coating and quality service. Please feel free to submit information about your needs, your question or comment using the convenient contact form below. Drawings may also be submitted. All inquiries will be responded to in a timely fashion.

Superior medical devices require superior coatings.

Our proprietary PTFE Natural® coated mandrels offer unmatched benefits.

Low Coefficient of Friction

PTFE Natural® coatings provide a coefficient of friction generally in the range of 0.05 to 0.20, depending on the load and sliding speed.

HEAT-RESISTANCE

PTFE Natural® coatings can operate continuously at temperatures up to 500°F (260°C) with intermittent processes up to 550°F (288°C) and can be used for intermittent service up to 600°F with adequate ventilation.

Non-Stick

Very few solid substances will permanently adhere to a PTFE Natural® coating. While tacky materials may show some adhesion, almost all substances release easily.

CHEMICAL RESISTANCE

Chemical environments usually do not affect a PTFE Natural® coating. Only molten alkali metals and highly reactive fluorinating agents are known to affect this coating.

ROBUST COATING

The proprietary PTFE Natural® coating process enhances the substrate bonding surface to provide optimum lubricity without flaking or cracking.

NON-WETTING

Since PTFE Natural® finishes are both hydrophobic and oleophobic, cleanup is easier and more thorough.

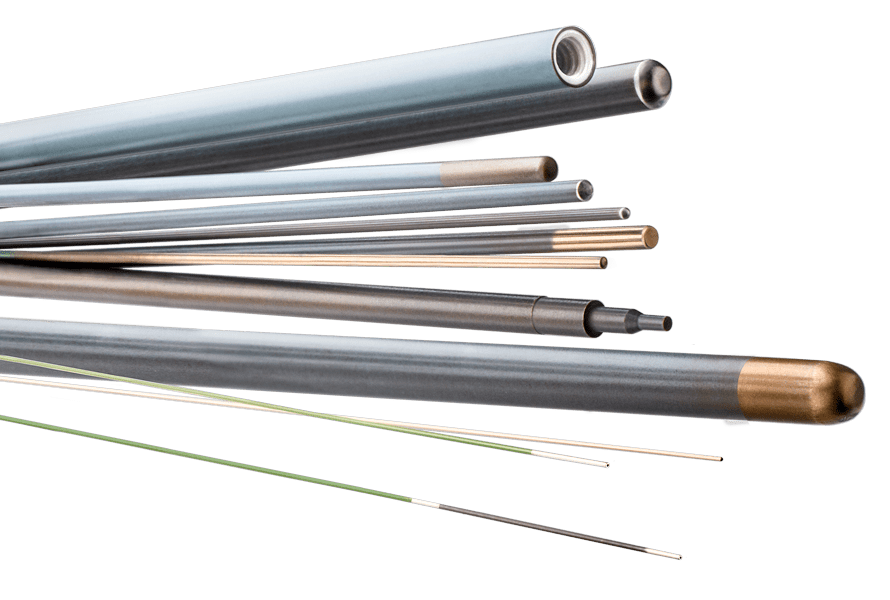

Coatings We Can Apply

Materials We Coat