About

Our Promise

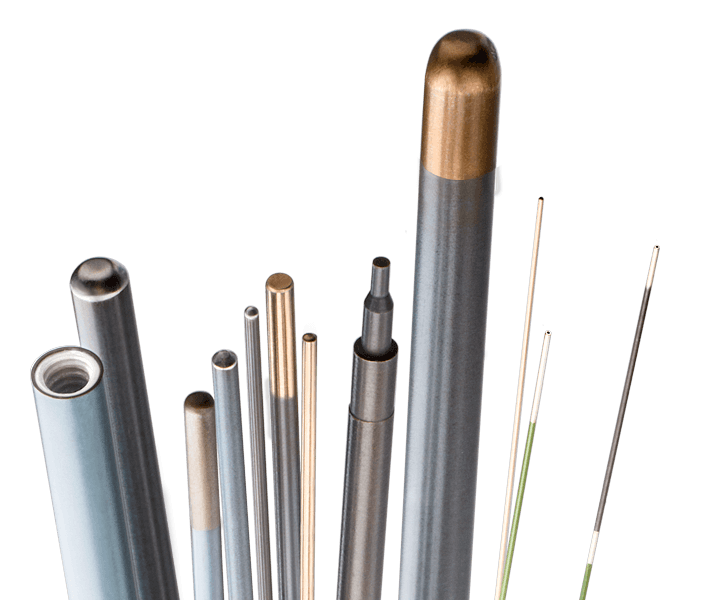

At Applied Plastics, we are the design engineer’s secret weapon. Our trademarked PTFE Natural® coating is applied to a variety of metals, including stainless steel, nitinol and silver-plated copper and used in numerous applications like mandrels, pull wires, core wires, hypotubes, stylets and guidewires. We are committed to providing our customers with market-leading coated mandrels, wire and lubricious products that enable the manufacturing of innovative life-saving devices.

- Our PTFE Natural® product has best-in-class quality, consistency, precision, durability and lubriciousness.

- We recognize speed is important to your business and carry an extensive inventory of PTFE coated wire diameters to meet your OD requirements.

- We’re a solutions partner with deep technical expertise.

Applied Plastics, Norwood MA

Our History

Over the past 65 years, Applied Plastics has evolved from family-owned small business to leading provider of cutting-edge advanced coated catheter components in the life-saving medical device industry. The company was founded by Frank Ring in 1953 and later became a family-run effort with son Dave Ring. Although Dave didn’t officially come onboard until 1977, there were many school-day afternoons and summer vacations spent at AP working alongside his dad Frank.

The company began by offering coatings for industrial purposes: you wanted it, you sent it; they coated it. In fact, one of the pioneers in the development of electrostatically applied powder coatings, Applied Plastics have been working with medical OEMs for over 30 years. As a result of their attentiveness to customer needs, the company started to receive more and more requests for lubricious PTFE coatings, higher volumes and continuous lengths of wire.

Applied Plastics built custom, state-of-the-art equipment to meet this demand for high-quality components held to tight tolerances. It took many years of fine-tuning to perfect it, but AP was tenacious in its pursuit to provide lubricious coated products with a repeatable process. This contributed to the quality and innovation that AP is known for today.

The company’s key to growth was, and continues to be, listening to its customers. Applied has partnered with design engineers for decades to understand their devices’ end-use application in order to manufacture PTFE coated components that meet OD, tolerance and performance requirements – factors that can influence the performance of life-saving devices.

While Applied Plastics has grown well-beyond the single-digit family-founded business it was 65 years ago, the company is still proud to say its team treats each other like family. It has had almost no turnover, and credits its long-term employees for much of the success it has seen.

Today, Dave Ring still serves a vital and supportive role as executive chairman, and renowned international medical device and contract manufacturing expert Thomas Barrett has taken on the role of CEO. The company is the leading supplier of PTFE coated products for use in the design and manufacture of advanced catheter systems.

Applied Plastics is a portfolio company of Vance Street Capital.

Why Applied Plastics?

Demand a best-in-class experience from your coating solutions partner.

Lubricity

Most lubricious, smooth and slippery surface compared to competitors.

Release

Best release properties in the industry.

Highest Tolerance

Can achieve the highest tolerances in the industry.

Durability

Longest lasting coatings coupled with ability to withstand high temperatures.

Proprietary Process

Unique PTFE Natural® formulation contains a very high percentage of PTFE.

Customization

Ability to provide highly customizable solutions to fit the customer’s exact needs

Capacity

Ability to process and fulfill large orders quickly.

Contact Applied Plastics

If you have a question, or a coating project you’d like to speak with us about, please feel free to use this form. We’re happy to work closely to identify your surface finish & lubricity needs, and help select the method of application to optimize your product performance. We are committed to providing a consistent coating and quality service. All inquiries will be responded to in a timely fashion.