Coating Services

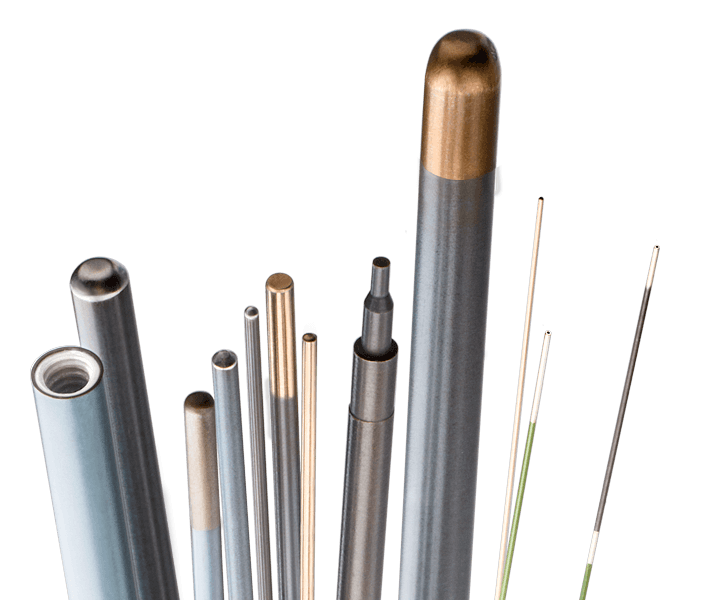

For over 65 years, Applied Plastics has been a pioneer in providing best in class coating solutions to the medical device market providing a lubricious, thin and robust coating layer with a smooth surface finish. Our coated products meet design engineers’ toughest tolerance & manufacturing challenges in numerous catheter development applications and products.

To assure the best possible adhesion and surface finish, we employ a wide range of coating application methods based on the substrate material and application of use.

Find out more about our Coating Services and PFTE Natural

- Coating Options Available

- Mandrel Coating Services

- Fine Wire Coating Services

- Hypotube Coating Services

- About PTFE Natural®

- Custom Component Coating

Why Applied Plastics?

Demand a best-in-class experience from your coating solutions partner.

Lubricity

Most lubricious, smooth and slippery surface compared to competitors.

Release

Best release properties in the industry.

Highest Tolerance

Can achieve the highest tolerances in the industry.

Durability

Longest lasting coatings coupled with ability to withstand high temperatures.

Proprietary Process

Unique PTFE Natural® formulation contains a very high percentage of PTFE.

Customization

Ability to provide highly customizable solutions to fit the customer’s exact needs

Capacity

Ability to process and fulfill large orders quickly.

Contact Applied Plastics

If you have a question, or a coating project you’d like to speak with us about, please feel free to use this form. We’re happy to work closely to identify your surface finish & lubricity needs, and help select the method of application to optimize your product performance. We are committed to providing a consistent coating and quality service. All inquiries will be responded to in a timely fashion.